NEXTEAM LAUNAGUET MACHINING

Z I Lacroix – 7 impasse de la Feuilleraie – 31140 LAUNAGUET |+33 (0)5 34 27 36 00

The company (formerly Gentilin) has been based on the outskirts of Toulouse, the aerospace capital, since 1962.

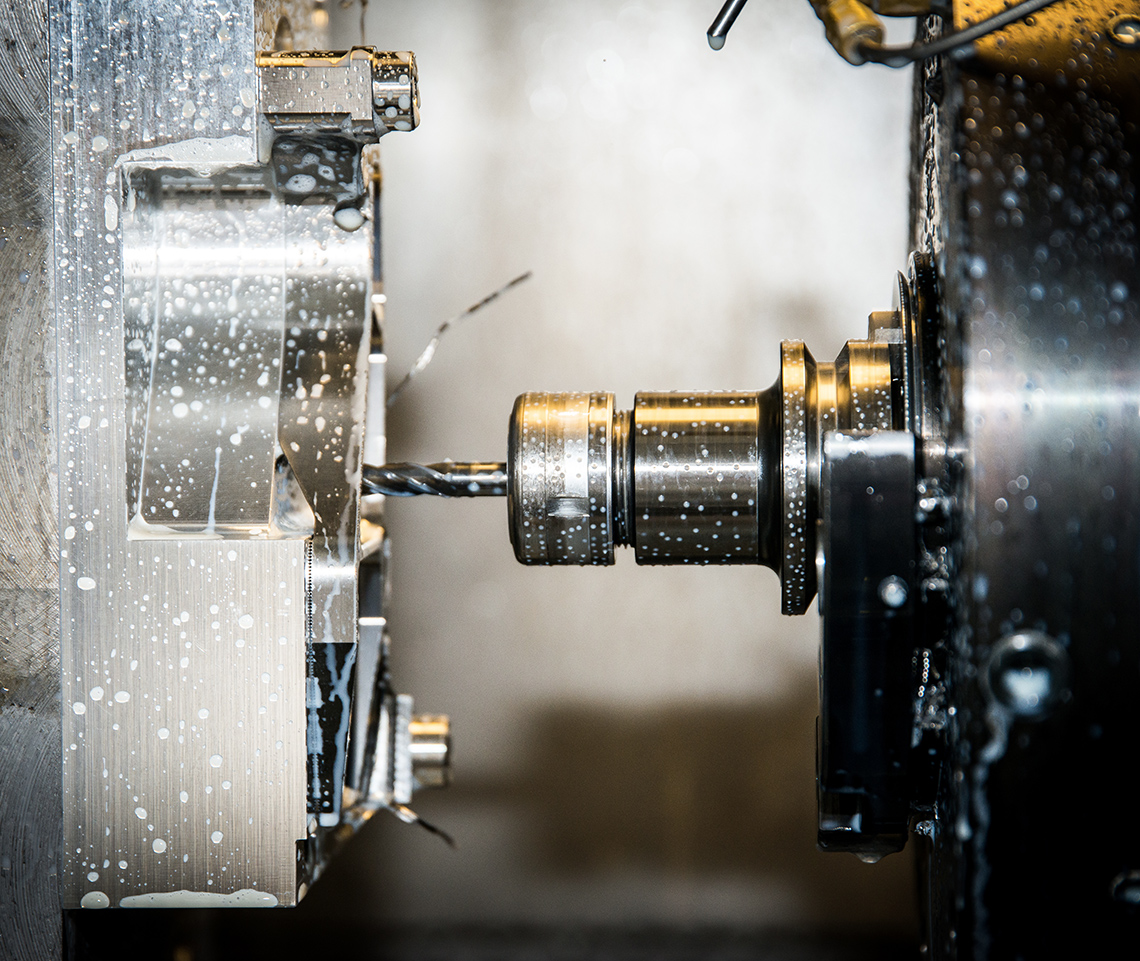

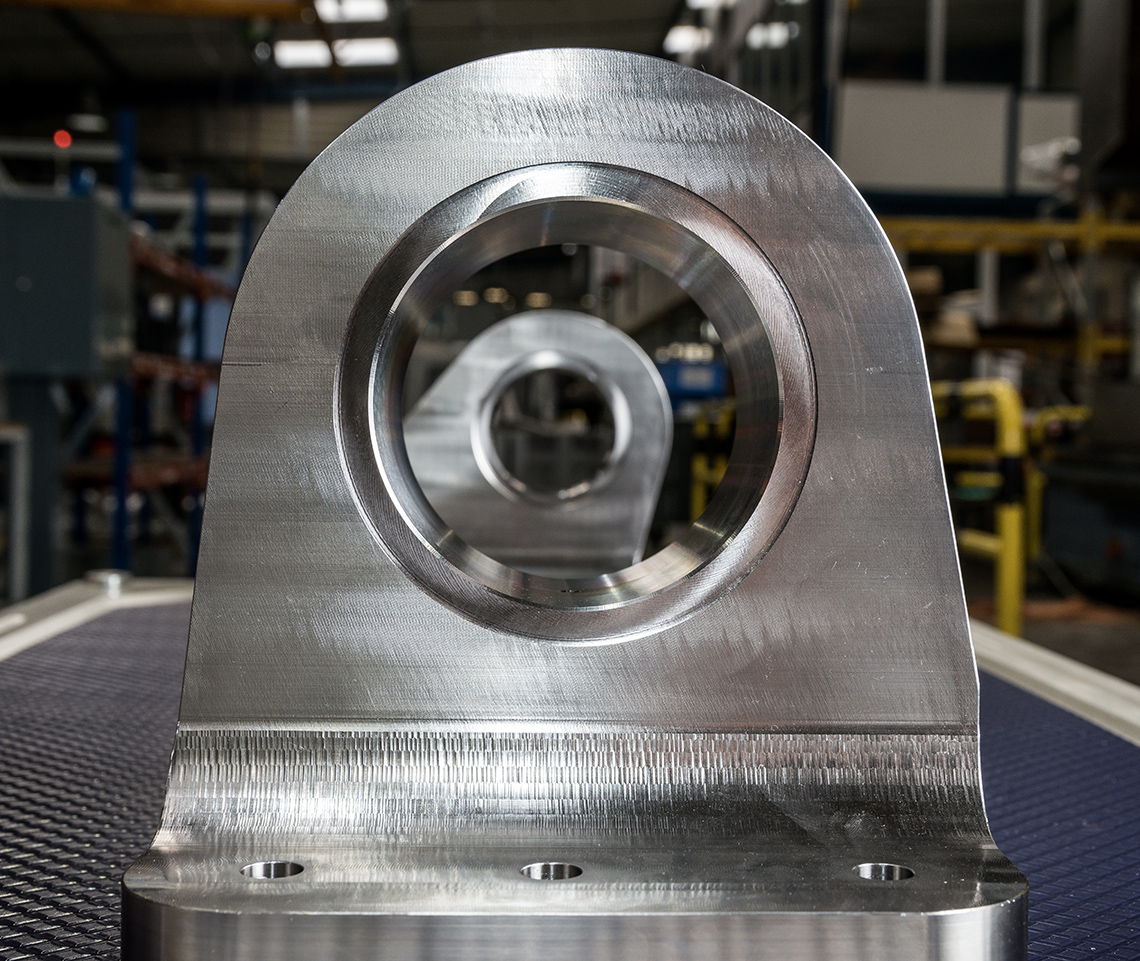

From the outset, the site has focused on machining hard materials, in particular titanium, which is used extensively in today’s aerospace industry. It’s been a winning bet for the founders and all the employees, who over the years have built up a wealth of experience in this field.

The company has also developed complementary activities such as assembly, maintenance and repair, materials management and storage, the AOG Speedshop and, very recently, titanium 3D printing.

Today, it is around complex sub-assemblies and work-packages that the business is developing.

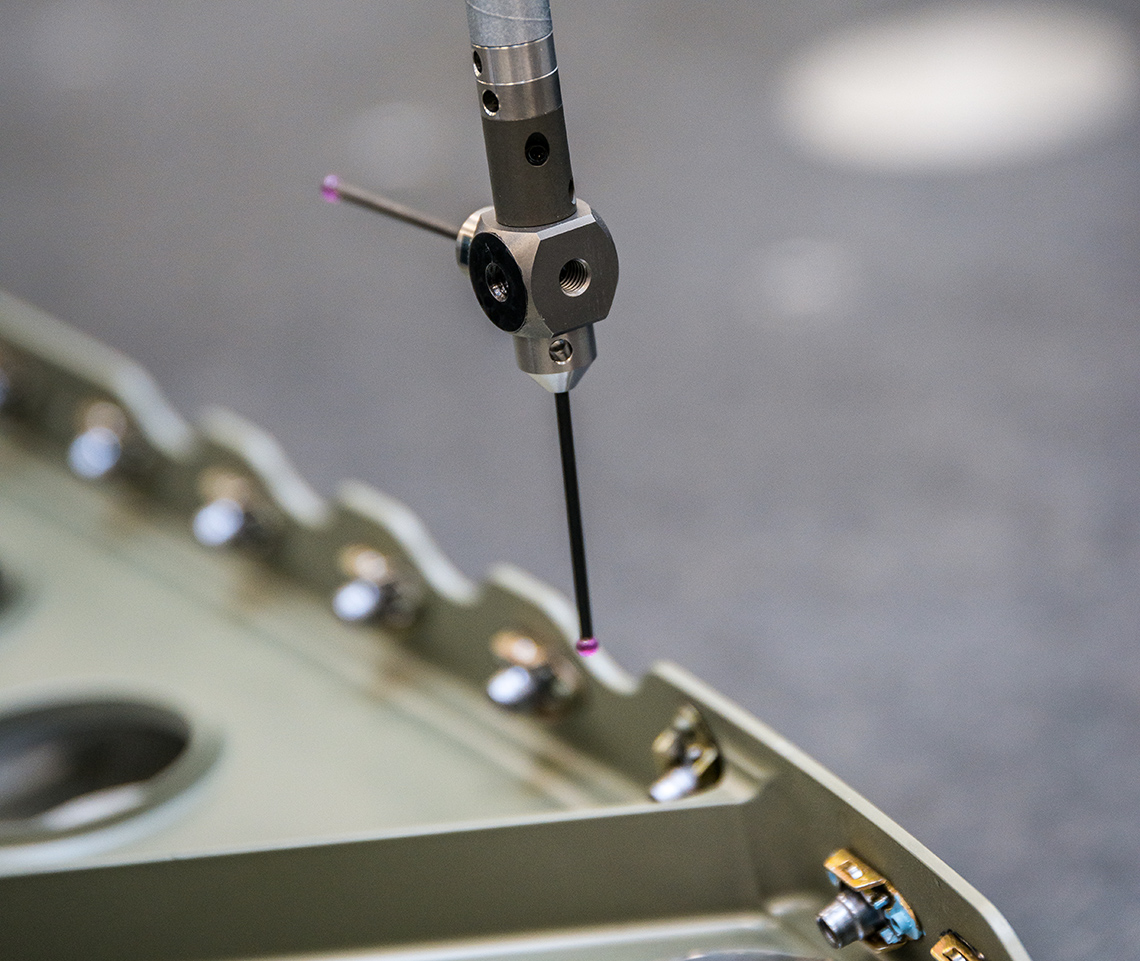

A partner to the aerospace industry since its inception, the company has adapted its production resources to keep pace with the rapid developments in this particularly demanding sector. With a strong presence in the Toulouse region, its team aims to be responsive and efficient for its customers, who can count on total reliability from the manufacture of high-precision parts to the maintenance of aeronautical equipment.

Key data

Expertise

Our areas of expertise

Machining / Assembly / Maintenance and Repair, Material Management and Storage, AOG Speedshop / Painting / Quality / Titanium 3D printing…

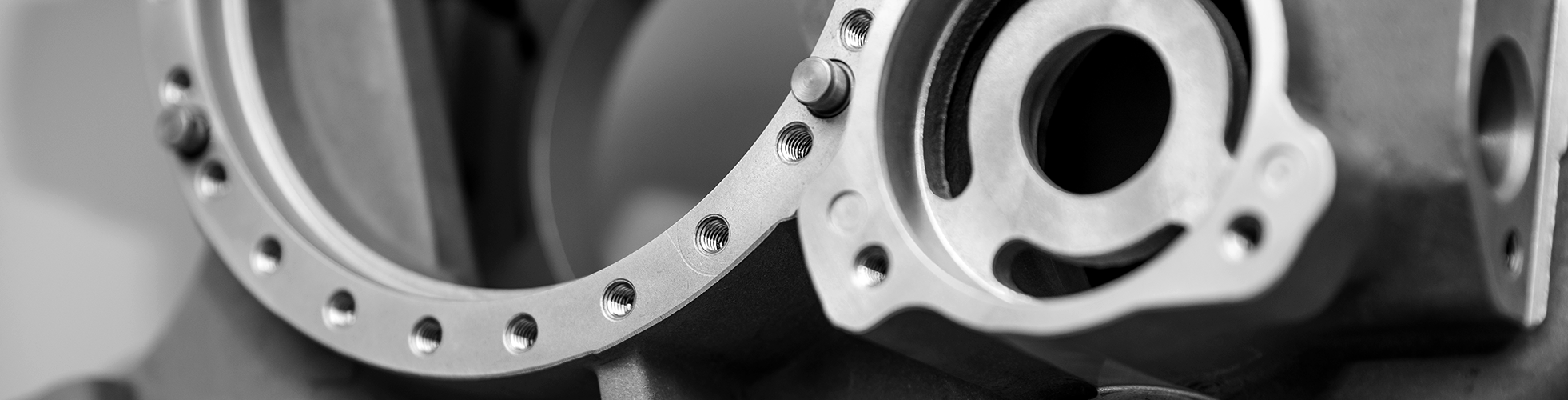

Machined products

Small and large hard metal components

Assembled products

Mechanical assemblies (cockpits, hatches, doors), engine nacelles and masts

Certifications

All of the group's sites are certified ISO 9001, the international reference standard for quality management.

Jobs at Launaguet

There are currently no vacancies.