Material management and storage

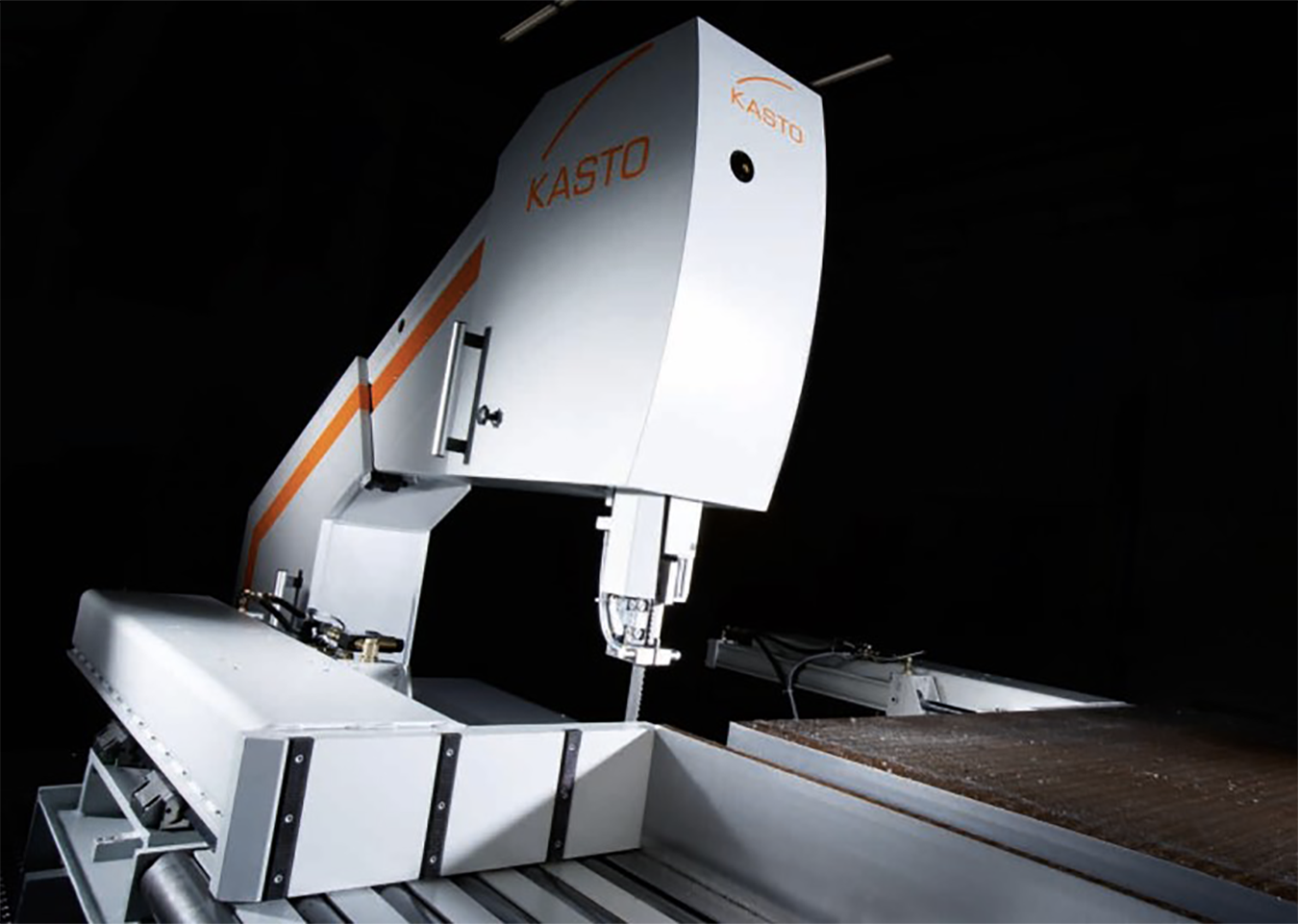

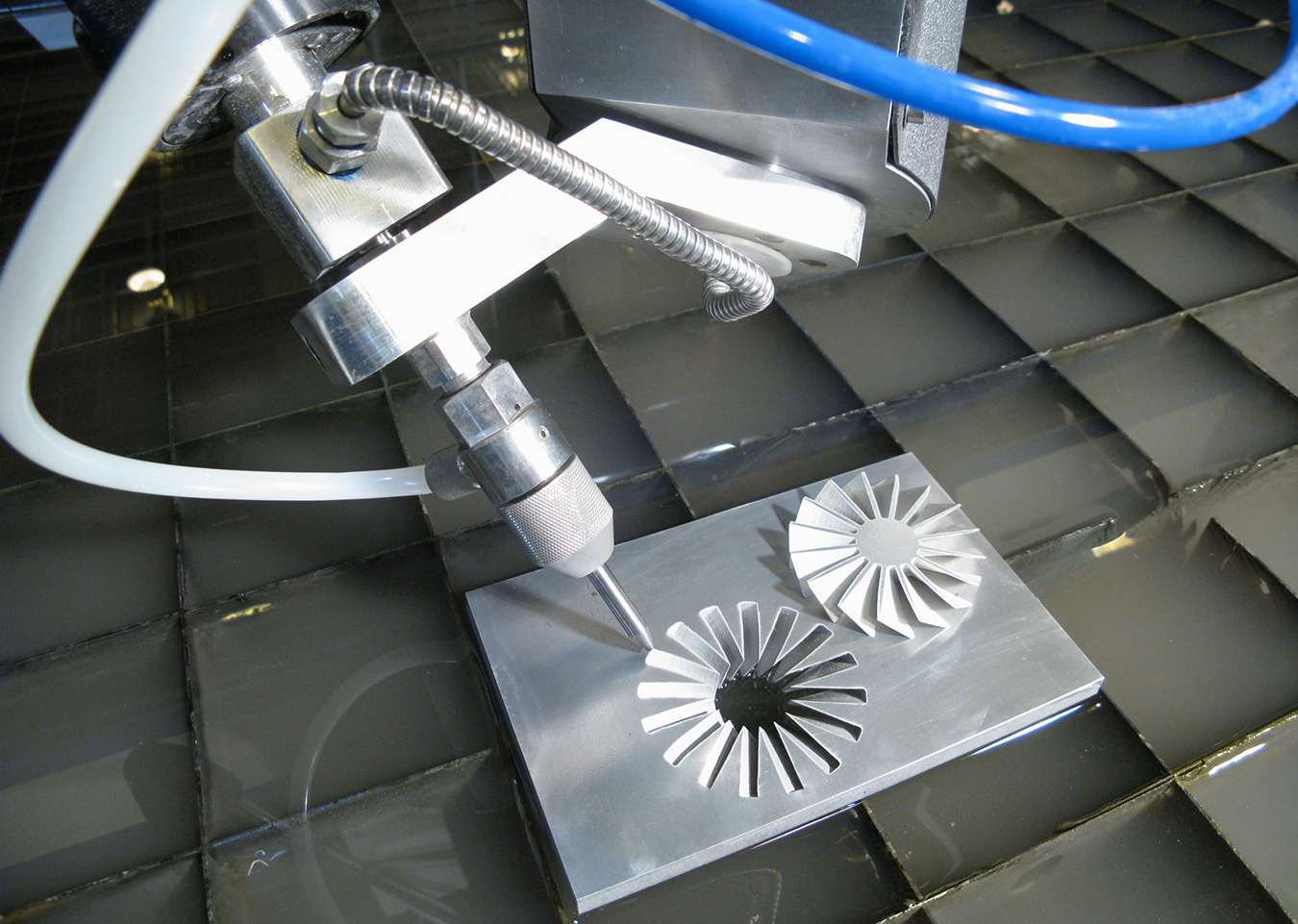

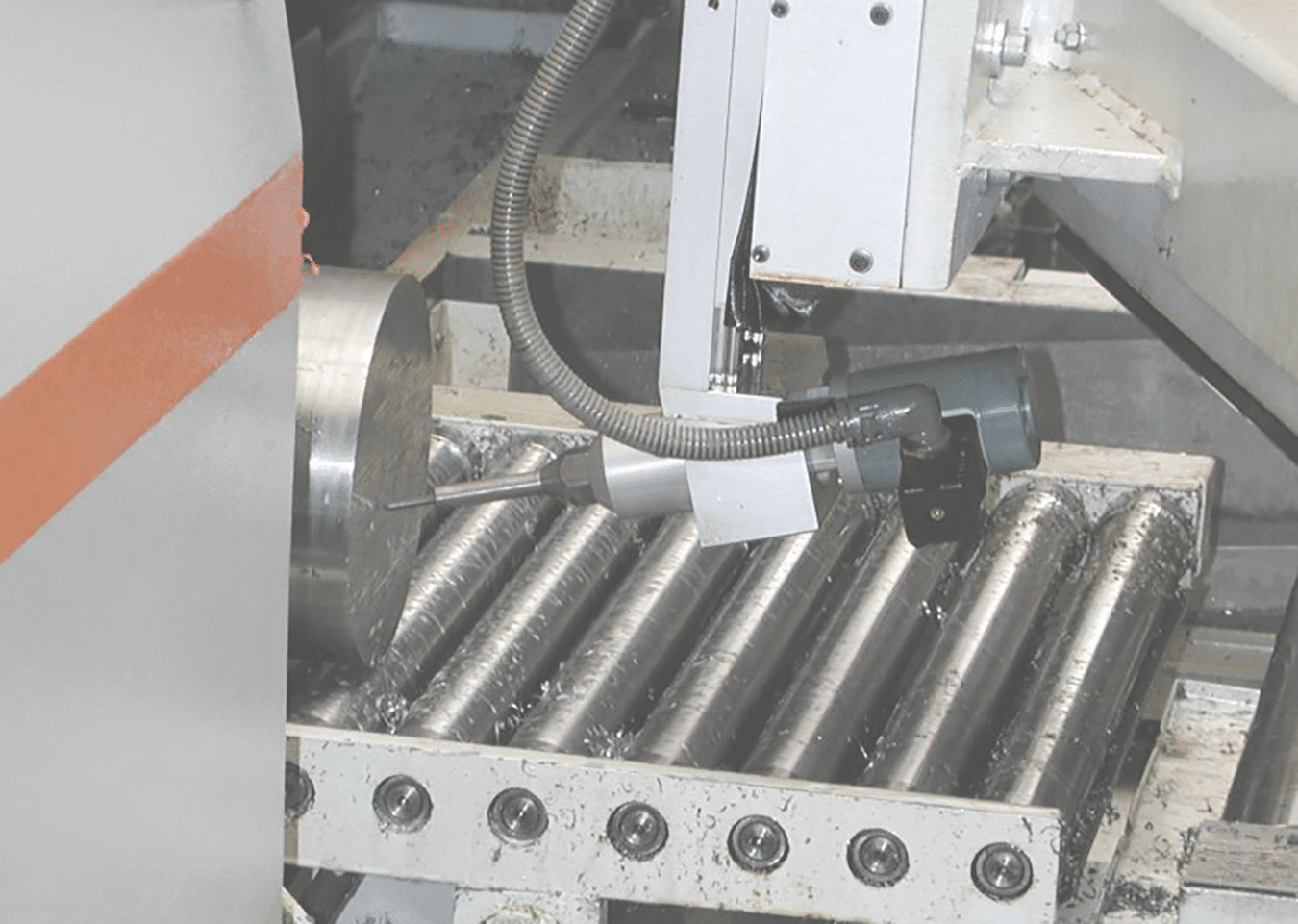

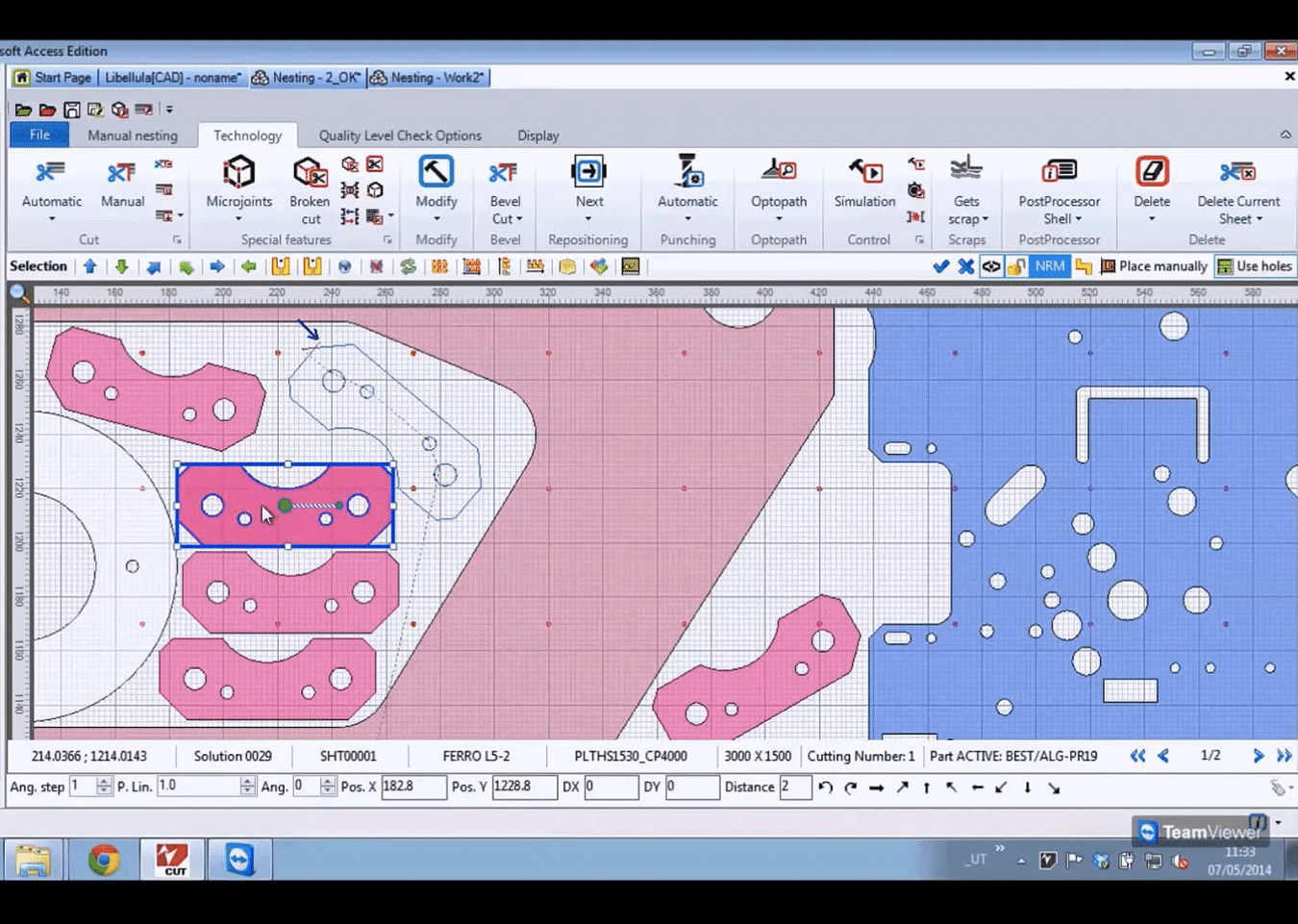

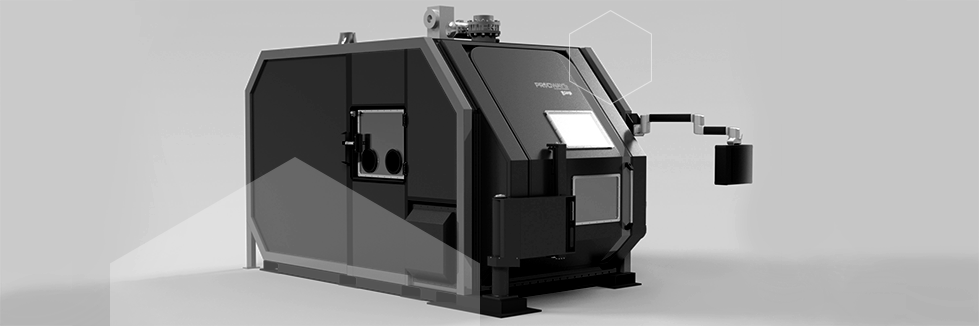

In order to control its production costs and optimize its processes throughout the supply chain, Nexteam has invested in a plant specialising in transformation of raw materials specific to the field of aerospace (stainless steel, titanium, Inconel and lithium) equipped with water-jet cutting equipment and thoroughly up-to-date manual and automatic saws.

Thanks to these very modern and efficient production machines, the Group manufactures semi-finished products in Launaguet for its various production sites (block-form, cast, extruded, forged) and provides its clients with storage, cutting and logistics services for raw material, in a dedicated 2,500m² building.

The combination and 5 axes cutting of flows as well as the speed of implementation are real assets for NEXTEAM. With an average of 600 tonnes transformed per year of initial capacity, they guarantee a better level of client service.